The HQ series offers a fast, reliable and cost-efficient solution for the counting and packaging of unmixed, single type or single flavour products. The counting machine can be placed... Read more >

Home > Industrial >

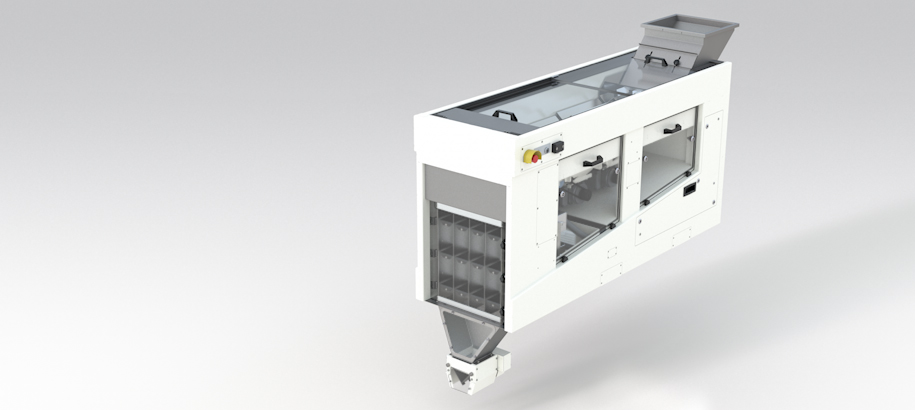

HQ series

- Standard or fully custom-tailored

- Scalable output

- 100% counting accuracy

- Suited for 24/7 operation

- Low maintenance, high reliability

HQ series

The HQ series offers a fast, reliable and cost-efficient solution for the counting and packaging of unmixed, single type or single flavour products. The counting machine can be placed directly on top of a packaging machine for the filling of bags or placed over a conveyor belt to discharge the product counts into all sorts of different packaging’s. The versatility of the counting machine extends to the possibility of counting a large variety of different products in bulk quantities or single piece discharges into any package. A guaranteed accuracy of 100% is one of the advantages of counting vs weighing.

Proven low-maintenance, maximum uptime, silent operation and the highest safety standards are key features of these high standard counting machines that have found their way to many of world’s largest confectionery and consumer goods companies.

The HQ series includes several models for different output capacities. Depending on the type of product and desired output, all HQ models can be delivered as standard machines or be designed for custom applications including the amount of memory flaps and vibrating channels.

Typical output up to 175 discharges/minute. Actual output speeds are related to the number of counting channels and memory flap levels.

Configurations

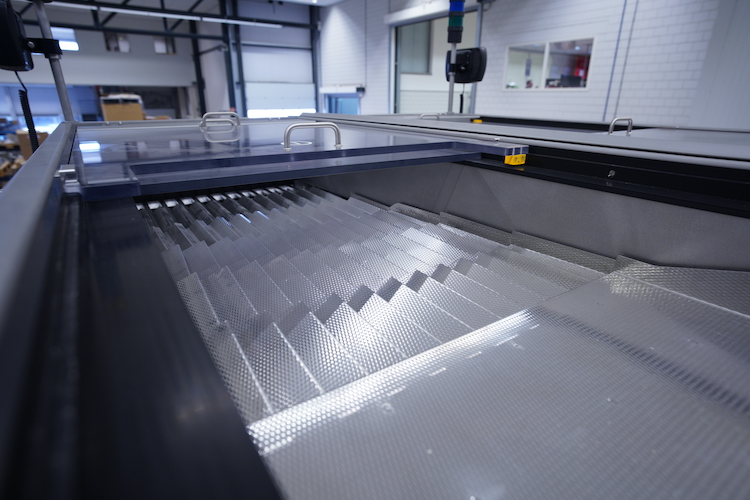

For accurate, fast piece-by-piece product counting, excellent product separation is key. A dosing system (or feeding belt) is used to deliver the product bulk to the counting machine. The product is loaded into a bulk hopper, and then gradually transported to the counting machine by a vertical or horizontal conveyor belt where the product is evenly dosed onto the first vibratory plate in small portions. The vibratory plates are used to properly separate the products and transport them to the scan unit. All models are configurable with 4, 6, 8 or 12 counting channels depending on the quantity and size of the products.

A single product counter can be used in combination with a simple tub box, carton conveyor or can be placed on an elevated platform to discharge the product counts into any industrial type of packaging machine such as a vertical bagger a cartoner or a rotary container filler.

Adding a second counting machine can double the output or can be used to fill a package with two different sorts of product or flavors to create precisely assorted product mixes such as assorted chocolate gift boxes any number of counting machines can be placed over a bucket conveyor with each counter processing a different flavor. This way, each bucket will be filled with a complete assorted product mix that can be discharged into any kind of package. At the end of the bucket conveyor, multiple discharge stations can be installed such as a manual fill unit, a tub or box filling conveyor or an automatic discharge station to release the product counts into any industrial bagger or cartoning machine.

Configurations or special requests can be discussed with our sales engineers.

Applications

- Confectionery

- Beverage capsules

- Detergent pouches

- Nutraceutical gummies

- Bakery products

- Hardware parts

- Medical devices

Video

Technical data

| Available models | HQ, HQF and HQI |

|---|---|

| Number of counting channels | 4, 6, 8, or 12 |

| Number of memory flap levels | 1, 2 or 3 |

| Nominal frame size | 400 mm or 600 mm |

| Output | up to 175 discharges/minute* |

| *Related to the product, number of counting channels and memory flap levels. |